Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Products

Model No.: CSJ/CSC Seres

Brand: Huanghewhirlwind

Blade Type: Continuous Boundary

Manufacturing Process: Sintered

Application: Ceramic

Packaging: Wooden case or Carton

Productivity: 4000 Pieces/Month

Transportation: Ocean,Land,Air

Place of Origin: China

Supply Ability: 48000 Pieces/Year

Certificate: ISO9001,CCC

HS Code: 82023910

Port: Qingdao,Guangzhou,Lianyungang

Payment Type: L/C,T/T

Incoterm: FOB,CFR,CIF,FCA,CPT

Introduction:

J-Slot Tile Blades

Application Data: Wet Cut Sintered Diffusion Bond Rim Height 10mm(.395")

CSJ:J-solt tile blades are ultra-thin tile/stone blades designed for cutting hard porcelain tiles,ceramics,granite and other materials.Sintered razor sharp rim provides a smooth feel and ease in cutting hard materials.Special J-slot laser cut seams release stress and eliminate wobbling during cutting.CTJ:Supreme J-slot tile blades employ a higher diamond grade and concentration.Ultra-thin razor rim with special J-slot laser cut seams.Made for the toughest cutting in hard material situations of dense porcelains and granites.The best blade for the most economical in production cutting.

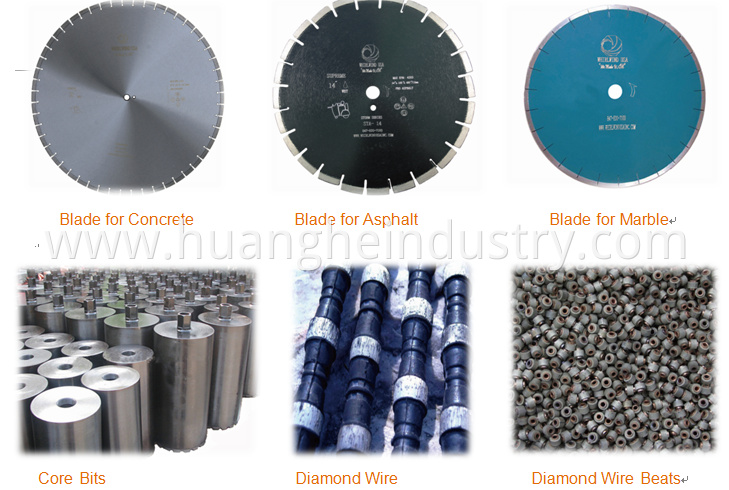

Diamond Tools:

Diamond Blades

Features:

High Diamond Segments

High Quality Diamond Blades

Diamond Blades for Marble Cutting

Diamond Blades for Ceramic Cutting

General Purpose Cutting Diamond Blades

Diamond Blades for Wet and Dry Cutting

Continuous Rim Ceramic Blades

Whirlwind continuous -rim ceramic blades are designed for fast cutting the most diffucult materials with porcelain and glass included. To mach the rigid core with a high concentration of diamond, they are able to cut straight after 14"

CGS: Good general purpose blades, value-priced for do-it youselfs jobs.

CPC: Having a higher concentration and grade of diamond for faster cutting and longer life.

Profile of Company:

Huanghe Whirlwind we represent a company that "makes it all" in terms of the production of synthetic diamond, metal powder manufacturing and diamond tool production, all encompassed in one source.

Founded in 1979 as a partnership of the Huanghe Group, A.L.M.T Osaka Diamond (Japan), Research Institute for Abrasives and Grinding and 23 subsidiary companies, Huanghe Whirlwind is the world's largest manufacturer of synthetic diamond, diamond and metal powders and diamond tools, blades and core bits. The Whirlwind facility covers 1 square kilometer of manufacturing space with 500 acres of plant under-roof and employs more than 5000 people. Net sales in 2014 amounted to USD 268 million.

Our engineering capabilities enable us to offer you a great experience in reliability, consistency and quality with ourworld-class diamond tools, One of Whirlwind's subsidiaries is a national research and development cen'ter, which holds the rights to hundreds of intellectual properties. We match the right diamond that we produce, to the right application. We employ the metal powders that we manufacture, to insure excellent results.

What does this mean to you?

Certificates of Company:

Presentation of Workshop:

Popular Products:

Remark:

When placing an order, the following information is required.

1. Diameter and specifications of product. We can custom manufacture to your specifications.

2. Arbol Holes Size. Pin hole where necessary and CTC between arbor and Pin hole.

3. Material to be cut(GP, natural stone, masonry, concrete, asphalt)

4. Hardness of the material.(hard, medium, or soft)

5. Type of machine. (flat saw, masonry saw, hand-held saws )

6. Wet o dry cutting. Commonly right angle grinders, hand held high speed saws are used dry. Masonry saws, floor saws are generally used wet, however, some applications are used dry.

7. Spindle speed (rpm)

8. Motor power (HP or KW)

Product Categories : Diamond Tools > Other Diamond Tools

Home > Products > Diamond Tools > Other Diamond Tools > Diamond Ceramic Blade (J-Slot/ Continuous rim)

Send Inquiry

Mr. huanghe

Email:

Send Inquiry Tel:86-0371-69102536

Fax:86-0371-69102092

Mobile Phone:+8615538150763

Email:

Address:26F, Landmark Plaza, A-1 CBD, Zhengzhou, China., Zhengzhou, Henan

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.